Quality Assurance

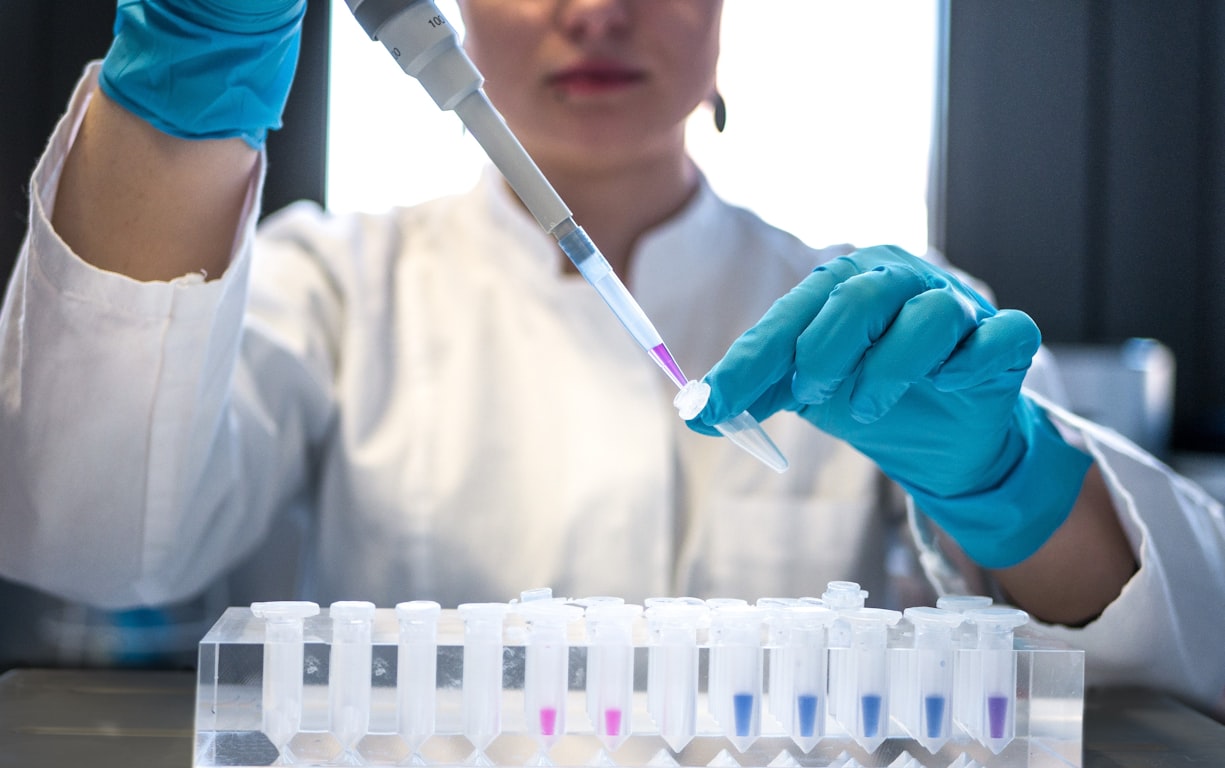

Our mission is to create and nurture long-term partnerships with our customers, growing together as we give the world the highest quality health products on the market. Our commitment to quality and your satisfaction is absolute. We will formulate and manufacture your product to the highest industry standards.

Experienced

Our dedicated team of formulators and flavoring experts has over forty years of experience in dietary supplement manufacturing. We specialize in liposomes, herbal extracts, and energy/nutrition products for athletes. Our proprietary processing technology is the only process in the industry that uses no heat, no high pressure, and no solvents. This allows us to manufacture formulas unsurpassed in effectiveness and stability.

Technology

Our technology uses non-GMO sunflower-derived lipids to encapsulate vitamins and nutrients. This encapsulation protects the nutrients from the destructive elements of the digestive system and delivers the nutrients for optimal absorption and benefits. Whether your goal is to improve existing products or create new ones, we are your ideal partner.

Creative Ideas

When you bring a formulation idea to us, we are committed to exceeding your expectations. We are registered with the FDA, but our testing standards surpass those set by the current Good Manufacturing Practices. Through meticulous processing and testing, we assure product identity, strength, composition, quality, and purity. We hold your formulations under strict confidentiality.

Our Commitments

Strict Standards

All raw materials and vendors are qualified using the strictest standards before approval.

Strict Testing

All raw materials and finished products are third-party tested for identity, strength, purity, and composition.

Expert Consultation

You can rely on our expert consultation from initial idea to finished product, including guidance regarding regulatory compliance and meeting label claims.

Establishing Standards

We will help you establish standards and markers to aid in the success of your product.

Documentation

We will create all the necessary documentation for your product’s compliance to FDA and international standards.

Good Manufacturing

We follow and exceed the requirements for Good Laboratory and Good Manufacturing Practices.

Quality Systems

Auditing

Our Quality Control Unit performs annual internal audits on every department and process to ensure cGMP compliance.

Sanitation

Records related to sanitation, production, receiving, distribution, and product and component quality are retained for four years beyond the final distribution of each lot.

Training

Employees are given GMP training on their first day. This training is refreshed at least annually. This is followed by two additional levels of training, particular to the employee’s department.

Frequently Asked Questions

Are your products third party tested?

Yes.

What kind of testing do you perform?

This depends on the ingredients and finished product. Typically we test organoleptic, microbiological, heavy metals, identification , and an assay when appropriate.

Is Valimenta/CELLg8® HACCP certified?

Yes, we are HACCP certified by SGS, an international entity that inspects and certifies manufacturing.

Does the company follow FDA's cGMP SOPs?

Yes, we follow 21 CFR Part 111, the FDA regulations regarding good manufacturing practices.

Is Valimenta/CELLg8® cGMP certified?

Yes, we are cGMP certified by SGS, an international entity that inspects and certifies manufacturing.

Are your facilities FDA registered?

Yes.